The new automated system will use cameras and sensors to monitor the build quality of each vehicle interior. It will be able to detect any defects or inconsistencies in the assembly process, allowing Tesla to quickly identify and address issues before they become a problem. This is an important step for Tesla as it continues its mission of producing high-quality vehicles that are reliable and safe for customers.

Tesla has also implemented other measures at Fremont such as increased automation, improved ergonomics, better lighting systems, and more efficient production lines. These changes have allowed them to increase their output while maintaining quality standards across all models produced at the factory.

The implementation of this automated system is yet another example of how Tesla is striving towards excellence in every aspect of their business operations from design through manufacturing processes - something that has been lacking in many automotive companies over recent years but which Elon Musk’s leadership team seems determined not only meet but exceed expectations on every front possible with regards to customer satisfaction levels when it comes time for delivery day!

*****

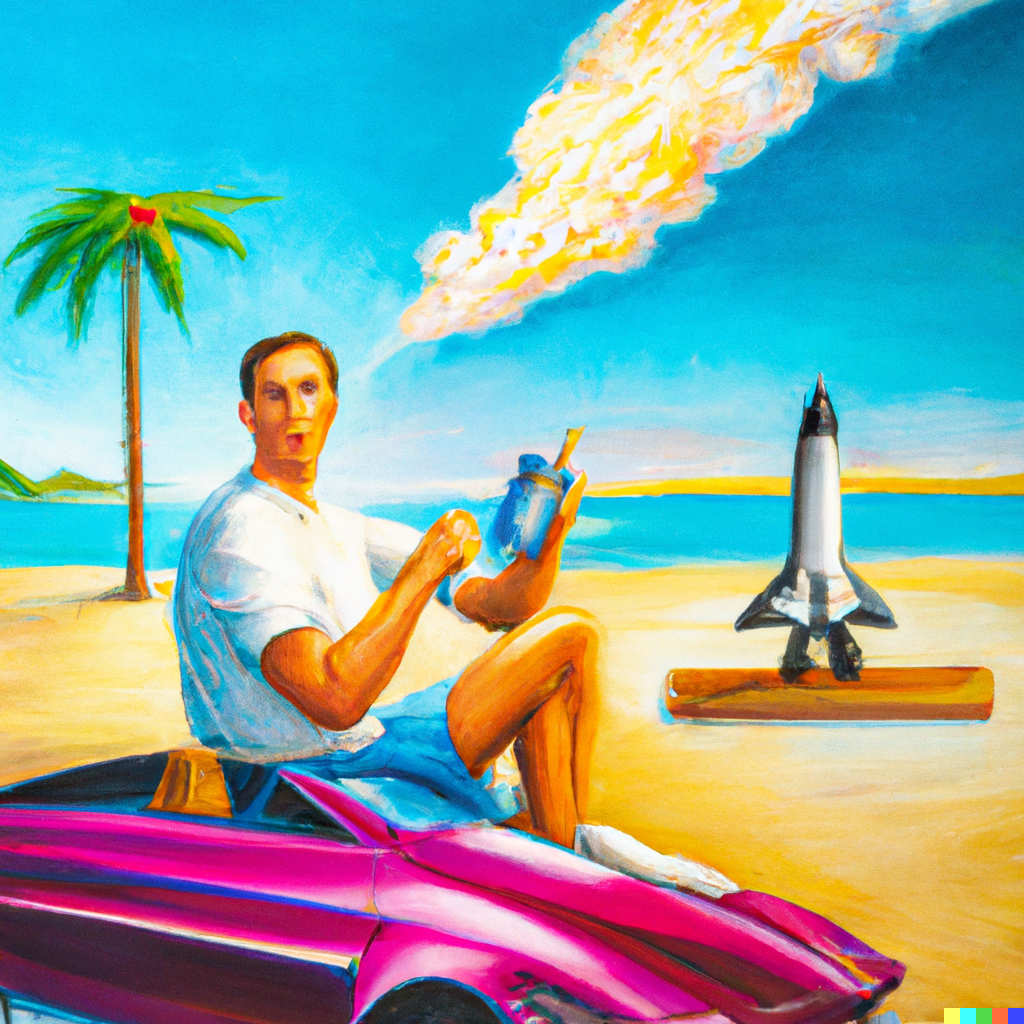

Thanks for reading! This website is an experimental news aggregator, with this article and image automatically generated using OpenAI’s ChatGPT & DALL-E. If any text or image was weird or inaccurate, it’s because the artificial intelligence became confused (this is especially true when it tries to include a year post 2021). We encourage you to check out the original article here. And be sure to give the real human authors some support by commenting, following them on social media, listening to their podcasts, etc. Thanks!